Your Plastic Foam and Film Densifier Company

JTW International designs and builds waste material conveying machines that handle trim, cutouts, and scrap directly from your production lines. These systems keep floors clean, reduce manual handling, and maintain a steady scrap flow to downstream recycling or densification equipment.

Our solutions range from simple trim inducer setups to complete industrial conveyor systems for waste across entire plants—each engineered for efficiency, reliability, and continuous duty.

Cutout and Edge Trim, Solved

Manual scrap collection leads to interruptions, safety risks, and higher costs. JTW conveying systems eliminate those problems by removing trim at the source.

Operational advantages:

-

Automatic trim removal keeps lines running without stoppages

-

Cleaner scrap stream improves material recovery and recycler value

-

Safer workflows with reduced forklift traffic and labor exposure

-

Flexible scope from single-line setups to plant-wide conveyors for scrap handling

You get consistent production flow, lower costs, and higher-value scrap ready for recycling.

Two Engineered Approaches to Scrap Conveying

Different operations demand different solutions. JTW provides two proven conveying technologies, each optimized for specific production requirements.

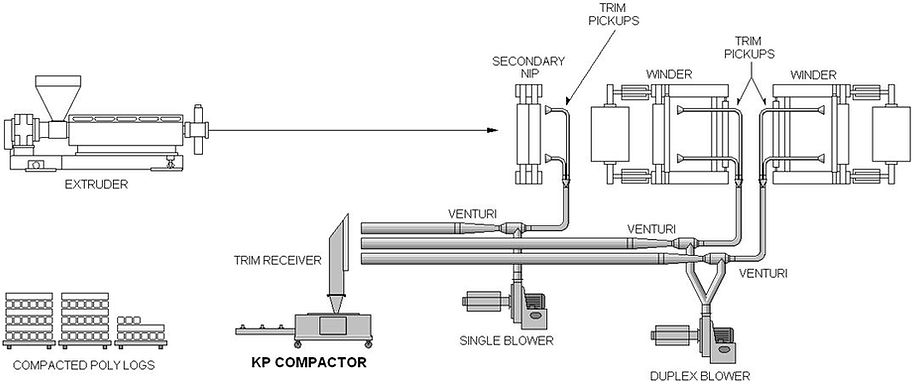

Venturi Trim Inducer Systems

-

Simple and efficient for foam and film trim

-

Standard package includes venturi, blower, AC motor, and inlets

-

Options for silencers, dampers, and starters

-

Off-the-shelf models available for quick installation

-

Mobile versions provide flexibility across multiple lines

The trim inducer is ideal for standard distances and volumes where dependable scrap removal is critical.

Cutter–Blower Systems

-

Handles higher volumes and longer conveying distances

-

Operates with plastics, paper, and other flexible substrates

-

Compact, low-maintenance cutters reduce downtime

-

Supports single or multiple trim pickups

-

Integrates with downstream plastic recycling equipment such as balers and compactors

For plants needing scalable scrap movement, cutter–blower systems deliver performance and durability.

Receivers and Integration Options

JTW systems include a range of receivers to match air volume and scrap type:

-

Scrap receivers for high-volume applications

-

Cyclone receivers for fine particles and fluff

-

Continuous trim receivers mounted directly to compactors or densifiers

All receivers are engineered for smooth airflow, minimal blockages, and direct compatibility with plastic recycling equipment. Whether integrated into densification, baling, or repelletizing, these options complete the conveying system for maximum recovery value.

Engineered for Your Line

Every plant has unique conditions—substrates, speeds, pickup points, and distances. JTW engineers each industrial conveyor system for waste to match those requirements.

Design options include:

-

In-line silencers for noise control

-

Dampers and diffusers for airflow tuning

-

Mobile skids or fixed installations

-

PLC-friendly controls for simple operation

All systems are manufactured in the USA with heavy-duty components designed for continuous industrial service.

Standard Packages and Available Options

Included in every system :

-

Sized inducer or cutter unit

-

Blower and AC motor

-

Trim inlets matched to your line

Optional upgrades :

-

Receivers (scrap, cyclone, continuous)

-

Motor starters, silencers, and dampers

-

Mobile frames for line-to-line flexibility

-

Interfaces for compactors, balers, or other conveyors for scrap handling

This flexibility ensures the waste material conveying machine is tailored to your operation, not the other way around.

Request a Consultation and ROI Projection

If you are reviewing plastic recycling equipment for sale, consider the value of a conveying system that turns trim and scrap into a controlled, marketable resource.

Contact JTW International today for a custom consultation. We’ll assess your waste streams, design the right configuration, and provide a detailed ROI projection—showing how our conveying systems cut costs and increase recovery value from day one.