Your Plastic Foam and Film Densifier Company

When PE foam scrap piles up, it consumes floor space, raises haul-off fees, and adds labor headaches. The AC Series Compactors from JTW International solve this by turning foam waste into rigid, stackable thermal logs. Each unit is a purpose-built foam scrap compaction machine that reduces disposal costs and creates a product recyclers will pay for.

Why Choose the AC Series?

Engineered and built in the USA, the AC Series is trusted by manufacturers that need dependable PE foam scrap densification. Every machine is designed for heavy-duty, continuous use while keeping operation simple:

-

Quick setup with single 3-phase power and compressed air.

-

Safe, quiet, and clean performance in busy plants.

-

Compact footprint—requires minimal floor space.

-

Produces uniform thermal logs with no baling wire.

-

Handles clean or dirty materials, including poly-coated paper and foil.

With the AC Series, scrap moves from being a costly problem to a controlled, revenue-producing process.

Model Lineup — AC Series Compactors

Each model is tailored to a specific throughput range, but all deliver the same reliable results in foam scrap compaction and recycling.

Proven Benefits of AC

Series Compactors

Operations that install AC Series units see measurable results quickly:

-

Lower disposal and haul-off costs.

-

Reduced bin rentals and landfill fees.

-

Freed floor space for production.

-

Less housekeeping and labor demand.

-

Up to 40,000 lb shipping loads in a 40-foot container.

-

A marketable product recyclers accept at a higher value.

One PE Foam Thermal LOG Machine pays for itself by cutting costs and generating new revenue.

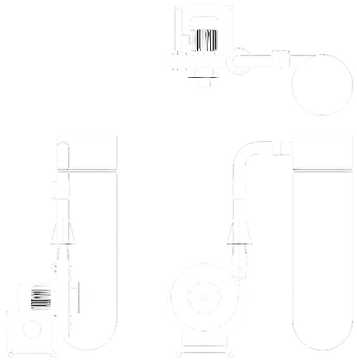

How It Works

The AC Series uses a patent-pending auger design to compress foam into dense, manageable logs:

-

Foam sheets, planks, or cutouts feed into the auger.

-

The material is compacted and pushed into a square log.

-

Heat forms a rigid outer shell, preserving the log shape.

-

Logs are cut automatically to preset lengths—anywhere from 8 to 44 inches.

-

The output can be palletized, shipped to recyclers, or sent straight into grinders and shredders.

This process increases bulk density up to 30 lb/ft³ compared to ~1 lb/ft³ loose foam. By replacing messy bales with clean, cut logs, the AC Series delivers higher efficiency with less dust and no strapping.

Integration & Versatility

AC Series Compactors are designed for seamless fit into plant operations. They can be set up as standalone units or tied into automated scrap handling lines. Beyond foam, they also process poly-coated paper, foil, and even PE film, functioning as a versatile PE Film Compactor Machine when integrated correctly. This makes them flexible for plants with mixed material streams.

Ready to Take Action?

The AC Series is the proven U.S.A built solution for pe foam scrap densification. It helps you cut costs, reclaim space, and turn waste into profit.

-

Request a material test to see performance with your scrap.

Talk with our engineering team to match the right model to your operation.

.png)

.png)