Your Plastic Foam and Film Densifier Company

The AD Series Densifiers from JTW International are engineered for manufacturers and recyclers processing PE, EPE, EPP, and EPS materials. Built in the USA, these systems form a complete EPS Foam Densification System, reducing waste volume, improving handling efficiency, and creating recyclable thermal bricks that can be sold for profit. Each unit is compact, durable, and designed for seamless integration with extrusion or converting lines.

Easy to Install and Operate

Fast startup. One 3-phase power connection is in minutes. PLC-based controls keep operation straightforward, so any trained team member can run the machine with confidence.

Flexible deployment. Run inline with extrusion or converting systems, or use a remote receiver for bags, cut-outs, and other loose scrap. Units can also be mounted on casters for mobility around the plant or recycling area.

For facilities planning to buy full melt densification equipment for recycling waste foam in the USA, the AD Series installs quickly, integrates cleanly, and keeps production moving.

AD Series Models

AD-60 SERIES

( Base Unit )

Application: Foam & film trim/waste

Material types: PE, EPE, EPP, EPS

Inlet Type: Hopper with Blade Shredder

Inlet Size: 21.5" × 19.5"

AD-60 HD SERIES

(Heavy Duty)

Application: Foam & film trim/waste

Material types: PE, EPE, EPP, EPS

Inlet Type: Hopper with Blade Shredder

Inlet Size: 28" × 29.5"

AD-60 D Series

( Dual Output )

Application: Foam & film trim/waste

Material types: PE, EPE, EPP, EPS

Inlet Type: Hopper with Blade Shredder

Inlet Size: 28" × 29.5"

All models can be equipped with optional accessories such as an infeed conveyor, elevating stand, or the exhaust ventilation system.

Foam Scrap Auger Densifier

At the heart of every AD Series unit is the Foam Scrap Auger Densifier, a precision-driven auger compactor that maintains continuous feed and uniform output. The auger design provides steady pressure throughout the melt cycle, ensuring consistent density and brick quality.

Systems are available in single- or dual-outlet configurations and can be operated inline or as mobile units on casters. With loads up to 40,000 lb per 40-foot container, these bricks ship efficiently and command a higher recycling value.

Engineered Shredding Systems

JTW’s dual-shaft, high-torque industrial shredder is purpose-built for Processing foam and film materials such as EPE and EPP. Each shaft is driven by direct drive gearmotors and supported by heavy spherical bearings for long-term reliability. Our shredders utilize anti jam programming to prevent material jams during the shredding process. Multiple inlet sizes allow configuration for various throughput requirements, ensuring consistent pre-processing in continuous-duty environments..

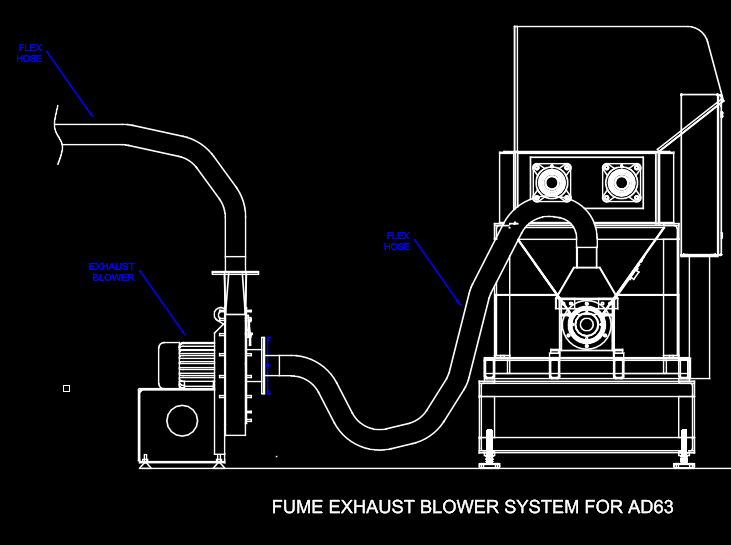

Exhaust Ventilation System

To maintain a better work environment, JTW offers an optional Exhaust Ventilation System that removes non-toxic but sometimes pungent fumes from the hopper and purge-die area.

This package includes:

-

1.5 HP blower

-

Exhaust hoods for the purge die

-

Flexible tubing from the hoods to the blower

Fan outlet ductwork is provided by others and not included in the quotation. The system helps keep production areas odor-free and compliant with facility air-quality standards.

Theory of Operation :

Foam sheets, planks, and cut-outs are compacted into rigid, high bulk-density Brick that stack easily and handle cleanly. Using an EPS and EPE Foam and Film Thermal Brick Machine design, the AD Series converts loose foam to up to ~30 lb/ft³ bulk weight—providing a clean, efficient way to cut disposal and transport costs.

The AD unit employs proprietary technology to compact materials to Homogeneous rectangular brick of densified Plastic. The material goes through a full melt Process pushed through the heating chamber and dies and flows out of the machine into the waiting form. No baling wire is required, dust and debris are reduced, and the densified bricks can be fed directly into most grinders or shredders for recycling.

Operational Benefits and ROI of AD Series Densifiers

Reduce bin-rental, haul-off, and landfill fees

Lower manual labor and housekeeping costs

Increase shipping density and sell densified scrap directly to recyclers

Operate safely and quietly via PLC-controlled interface

Supported nationwide by JTW’s U.S. service network

Each eps compactor machine is designed for long-term reliability and immediate cost recovery.

Get a Quote

Discuss your material stream and throughput goals with JTW International. Our engineering team will recommend the right AD Series configuration and provide a detailed ROI analysis for your facility.